The growth acts like a mechanism for drying the dirty water — also known as wastewater, which comes from homes, factories and the street. It’s reminiscent of a thin film of tiny living things (microbes) that adhere and grow to a surface. This yucky layer of slime is gross, but it actually helps to break down bad stuff in the water. As wastewater flows through areas with biofilm, microbes consume and transform harmful chemicals into more benign substances. This process makes the water cleaner before it is returned to rivers or lakes. Yimei Environmental applies special biofilm technology so that it can help enterprises to deal with wastewater in a smart and efficient way.

Biofilm technology wastewater treatment for wholesale buyers About biofilm technology in water consumption is thought to be the main source of human body infection, where chlorine is insufficiently disinfected.

If you are buying wastewater treatment systems in bulk, then biofilm technology is a wise move. And when microbes team up to form biofilm, they assemble a natural cleaning crew that never stops. Yimei Environmental’s biofilm systems are made to provide these little helpers with the perfect home in which they can live and work. This enables the microbes to clean the water more quickly and effectively than other approaches. For instance, biofilms can sit on the surfaces of tanks or pipes — and, in some cases, continue to operate even when water is moving briskly through them. That’s what makes the treatment so predictable and reliable. Plus, biofilms require less energy since the microbes do a lot of the work on their own — and that can mean saving money. Occasionally, people assume the biofilm might get stuck or dirty, but at Yimei Environmental there is no worry of that happening because water moves through the system well. Customers that purchase these systems in larger quantities report being able to process larger amounts of wastewater without any problem. That’s in contrast to factories or cities that can purify large amounts of filthy water at a time without getting bogged down. Plus, biofilm systems are flexible. They can process various kinds of wastewater, from having lots of chemicals to being largely natural waste. Buyers have needed that flexibility to adapt to changing water conditions. Indeed, thanks to biofilm technology from Yimei Environmental, wholesale buyers receive super-durable equipment that is easy to maintain and functional year after reliably working year. Which explains why a lot of businesses rely on this technology to enhance their wastewater treatment.

There are several good things that come from purchasing biofilm wastewater treatment systems in bulk from Yimei Environmental. First, big orders generally result in lower per-system prices. That means companies are more able to fit the treatment into their budgets. Otherwise, Yimei Environmental can readily deliver many units rapidly so that companies do not have to wait long before cleaning their wastewater. Another advantage is that when multiple systems are combined, they can act as a team. For instance, one system would barely clean the water at first, then the next system cleans it a bit more. This incremental cleaning makes it so the water is really clean by the end. Buying in bulk also means companies can plan better, as they receive all the gear they need at once. This prevents delay or added expense to purchase piece by piece. What’s more, Yimei Environmental provides support and guidance for large purchasers in setting up and maintaining what have indeed been high-performing systems. This kind of personal assistance makes a difference, because wastewater treatment can be complicated. For some potential buyers, space or the toil of operating many systems is a concern, although Yimei Environmental’s designs are compact and easy to use. Finally, because they buy in bulk, buyers receive consistent quality across all of their units. That consistency is crucial in businesses where clean water is a necessity. So those companies that are bulk buyers of Yimei Environmental’s biofilm systems are not just buying equipment, but a strong partner in making wastewater treatment easier and better.

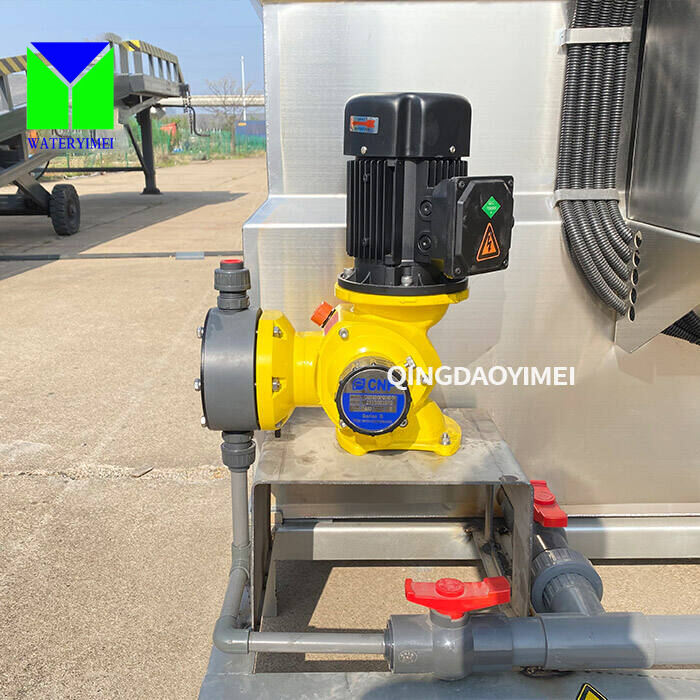

Biofilm reactors are special systems for treating dirty water, such as domestic and industrial waste water. In these reactors, small organisms called bacteria live and they grow on surfaces to create a slimy layer named biofilm. These bacteria dine on bad things in the water and they convert them to things that are safer. Getting the biofilm reactors to work just so is essential for achieving good cleaning. “This requires the bacteria-growing surfaces to be both clean and rough so that the bacteria can stick well.” Bacteria don’t readily stick to smooth surfaces. Secondly, we need to control the flow of water through the reactor very carefully. If the water is moving too fast, it can throw away the bacteria. If it returns to the magnet too slowly, then the bacteria don’t find enough food. The temperature and level of oxygen inside the reactor also have to be just right — bacteria thrive in particular conditions. Too hot or too cold can put a damper on their progress. Not enough oxygen can interfere with their ability to clean efficiently. It also prevents the biofilm from becoming too thick. When biofilm grows too heavily, it can disrupt the flow of water and minimize the effectiveness of cleaning. Reactors, then, tend to have methods for scraping older biofilm away or maintaining its balance. Yimei Environmental supports the design of biofilm reactors with the greatest surface, water flow, and air supply. By doing that, the bacteria remain healthy and are able to clean the water faster and better. Through sensors and smart controls, Yimei Environmental can monitor the reactor around-the-clock and make adjustments as needed. This allows biofilm reactors to operate at optimal levels without a break, so that waste can be well-cleaned before exiting our systems or being recycled. Optimising biofilm reactors seems to be the bridge toward ensuring safe and healthy water for people and nature.

Today many sectors prefer biofilm-based wastewater treatment, a smart and sustainable way to clean dirty water. Large factories generate a great deal of wastewater and have to take the bad things out — chemicals and germs — before they can release the water back into rivers or back into the environment itself. Biofilm treatment also employs natural bacteria that grow on surfaces and feed on these bad materials. This approach is gaining popularity because it works even for difficult waste and can process a lot of water. Another reason why industries enjoy biofilm systems is in that they require less space then other treatments. And, because biofilms allow bacteria to grow in layers, more of them can fit in a small area and purify water more quickly. This economical on the part of factories, which do not have to build big tanks or plants. And biofilm treatment is far less energy-intensive, because the bacteria do most of the heavy lifting themselves. It helps industries cut their bills and reduce pollution from the energy that they use. The biofilm technology developed in Yimei Environmental is both convenient and reliable to operate. A lot of industrial purchasers put their faith is Yimei Environmental, because the company ensures that things will keep running without much in the way of fixing or shutting down. The biofilm systems are also flexible to variations in the water quality. If the waste in a factory is different, the biofilm bacteria can adapt and continue to clean effectively. This is what makes biofilm treatment an adaptable option for most industriesaders. There’s also mounting pressure from both governments and consumers for factories to become more eco-friendly. These rules are met by biofilm therapy and are in agreement with it because they address the causes (and not just the symptoms), is natural and is free of harmful remnants. For these reasons, biofilm-based wastewater treatment is rapidly becoming a go-to technology for industrial purchasers seeking a safe, robust, and intelligent means of environmental protection.

Qingdao Yimei Environment Project Co., Ltd. was established 1988. It is located in huangdao District Qingdao City which has workshop biofilm in wastewater treatment of 36000 square meters and more than 130 kinds of treatment machinery. Our company experts engineering, powerful and specialized production bases and sophisticated fabrication equipment. Since beginnings, have gained enviable reputation for high-quality with low costs and advanced techniques. Our efforts are focused on the environmental issue.

have more than 130 kinds of biofilm in wastewater treatment for treating. part of Shandong Province Environmental Protection Industrial Association. Presently, we have 360 members workers, comprising 72 engineers and technicians. offer a broad range operations, which include manufacturing of environmental protection equipment, water treatment technology development, engineering construction and technical support.

R D team is highly skilled and experienced. team has rich biofilm in wastewater treatment in sewage technology along with extensive amount of experience in field. They are able to develop innovative technology and equipment that adapts the changing needs of sewage. Regardless industry size the company can offer custom-designed solutions.

waste treatment plant exports many nations, such as America, Saudi Arabia, Peru, Columbia, Vietnam, Thailand, Philippines, Kenya, Iraq, Sudan etc. With high-quality products, competitive prices advanced biofilm in wastewater treatment, earned an excellent reputation with customers. Our spare parts readily available clients. With over 10 years' experience, the oversea install team can provide you the most effective solution using the most reliable technology, if you encounter any issue in the wastewater industry, please contact us.

Copyright © Qingdao Yimei Environment Project Co., Ltd. All Rights Reserved Privacy policy