· Премиум суровини с гаранция за качество.

· Ефективно пречистване със стабилно качество на изходящата вода от клас 1А.

· Компактна конструкция за лесна надземна или подземна инсталация.

· Напълно автоматична работа осигурява стабилни експлоатационни показатели.

Информация за продукта

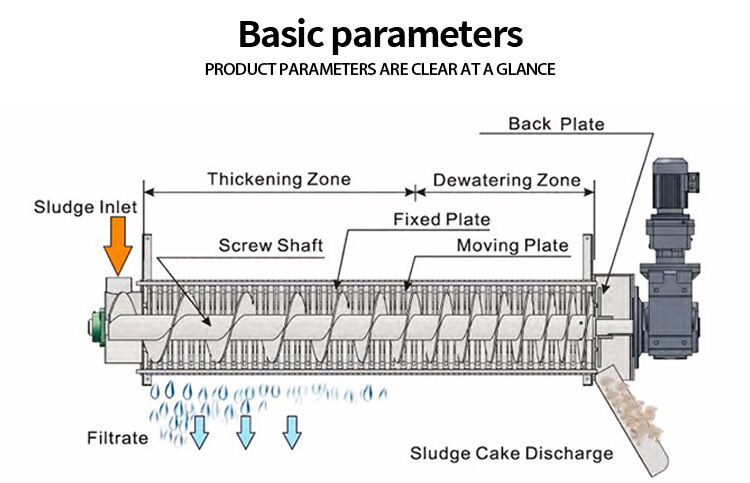

1. Чрез помпата за подаване на утайка, утайката се транспортира до порта за подаване на утайка

2. Утайката се транспортира до резервоара за флокулация след регулиране на дебита чрез

резервоара за дозиране, и утайката се напълно разбърква и смесва от разбъркиващото устройство

3. След напълно разбъркване чрез разбъркиващото устройство, за да се образуват големи флокули, те се изпращат в основния корпус

на винтовия стакер

4. Флокулите, изпратени в частта за концентриране, се концентрират чрез гравитация, докато се придвижват към

посока на частта за дехидратация

5. Междинното пространство между плуващия пръстен и фиксирания пръстен на частта за дехидратация става по-тясно

и дехидратацията се допълнително наляга чрез регулиране на задната налягаща плоча, разположена на изхода за отпадъчни продукти,

и накрая кекът се изхвърля

Характеристики на продукта

1. Ниска мощност, висок въртящ момент, работа при ниска скорост, по-малко повреди

2. Изискано обработващо технологично решение, ниска цена

3. Малка заета площ, висока степен на автоматизация

4. Осигуряваме OEM услуга, 1 година резервни части безплатно.

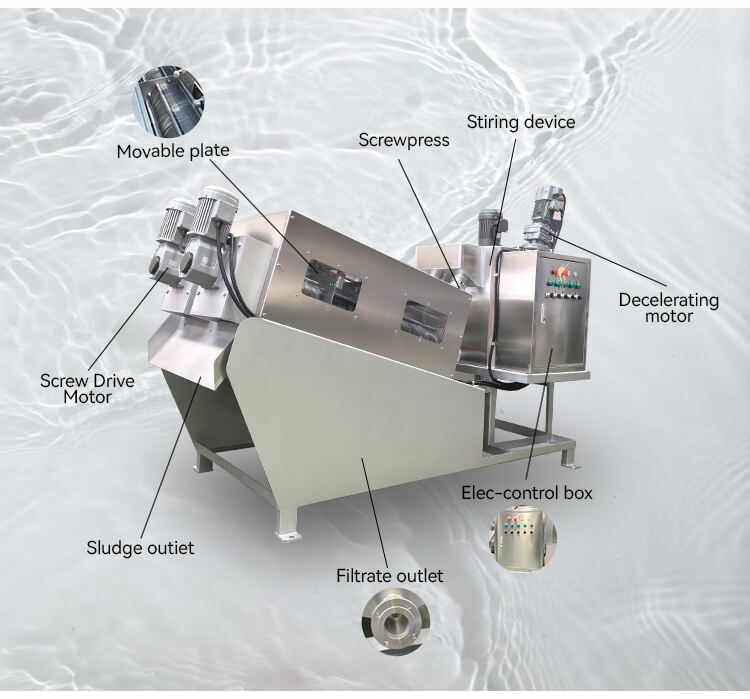

Екстериорен дизайн:

Основният корпус е изработен от неръждаема стомана SS304, която притежава добра заваряемост, устойчивост на топлина, корозия

и устойчивост при ниски температури

Интериорен дизайн:

Фиксираното пръстен и плуващото пръстен са поставени един върху друг, за да образуват цилиндър, а винтовият вал

минава през тях, за да образува филтриращо устройство

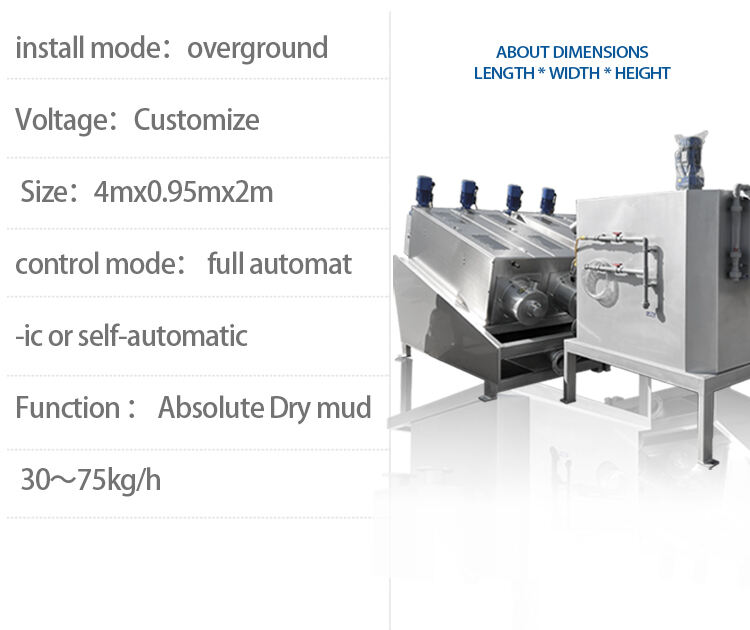

начин на монтиране: над земята

Напрежение: По поръчка

Размер: 4м x 0,95м x 2м

режим на управление: напълно автоматичен или полуавтоматичен

Функция: Абсолютно суха кал 30~75 кг/ч

Ще осигурим качествени продукти и искрена услуга, за да създадем ситуация на взаимна изгода, първокласно производство

и стриктно управление, Най-пълна цена за вас, 5 причини да ни изберете: Зелено – спестяване на енергия

дълъг работен живот, производство в продължение на много години, якост и ширина, Стабилни представяни и гарантирано качество

Гарантирано качество за вашите нужди, Директно доставяне от фабрика, намалена цена

1. Как да закупя вашите продукти по идея?

A: Можете да ни предоставите източниците на водата, качеството на водата, дебита и площта (свържете се с нас за повече подробности).

2. Как да платя?

A: Приемаме TT и LC, като TT се предпочита. Депозит от 30% преди производство.

70% салдо преди зареждане чрез TT.

3. Какъв е срокът за доставка?

A: Зависи от количеството на поръчката. Обикновено срокът за доставка ще бъде в рамките на 4 до 6 седмици.

4. Как се опаковат продуктите? A: Използваме стандартно опаковане. Ако имате специални изисквания за опаковане, ще опаковаме

според изискванията, но таксите ще бъдат платени от клиентите.

5. Как защитавате оборудването си от корозия?

A: Използваме световноизвестни бояди, като SigmaCoatings, PainBow и др. Освен това, боядисваме стриктно според

стандартния процес.

6. Как произвеждате вашето оборудване?

A: Нашата машинна обработка включва лазерно/плазмено рязане, автоматично заваряване, CNC рязане и огъване.

7. Как се монтира след пристигането на оборудването в дестинацията? A: Ще ви предоставим подробни илюстрации. Ако е необходимо

при необходимост ще изпратим техници да ви помогнат. Въпреки това, таксата за виза, самолетните билети, настаняването и заплатите

ще се плащат от купувачите.

Авторско право © Циндао Йимей Проект за околната среда Кo., Ltd. Запазени са всички права. Политика за поверителност