· Premium raw materials with quality assurance.

· Efficient purification with stable, Grade 1A effluent quality.

· Compact design for easy above-ground or underground installation.

· Fully automatic operation ensures stable performance.

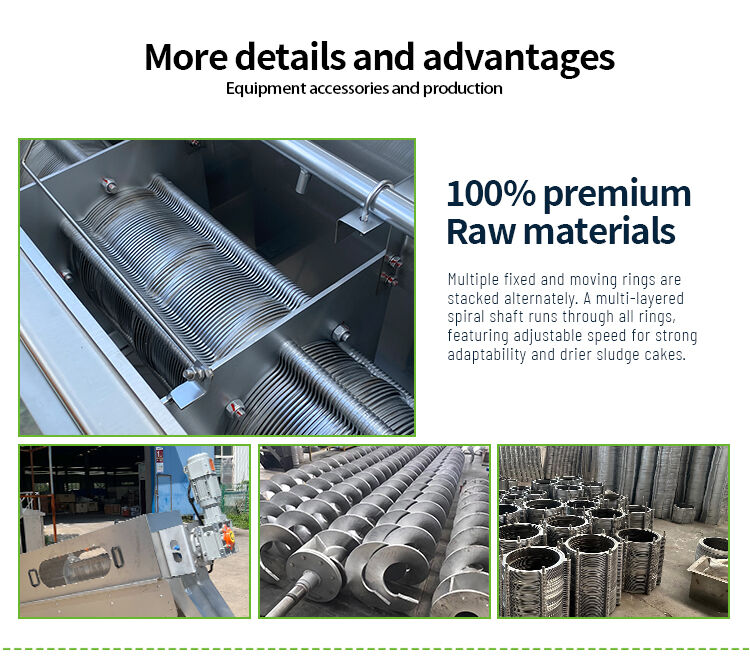

Fixed Rings & Moving Rings

Stacked alternately to form a filterchamber; tiny gaps between the ringstrap sludge flocs while

enabling smoothwater drainage.

Screw Shaft

Provides forward propulsion for sludge,qenerates stronq extrusion force viapitch and shaft variations,

and drivessludge from the thickening section tothe dewatering section.

Plc panelintelligent automatic control system

Automatically adjusts chemical dosing, aeration time, and sludge return ratio based oninfluent

quality to prevent manual errors.

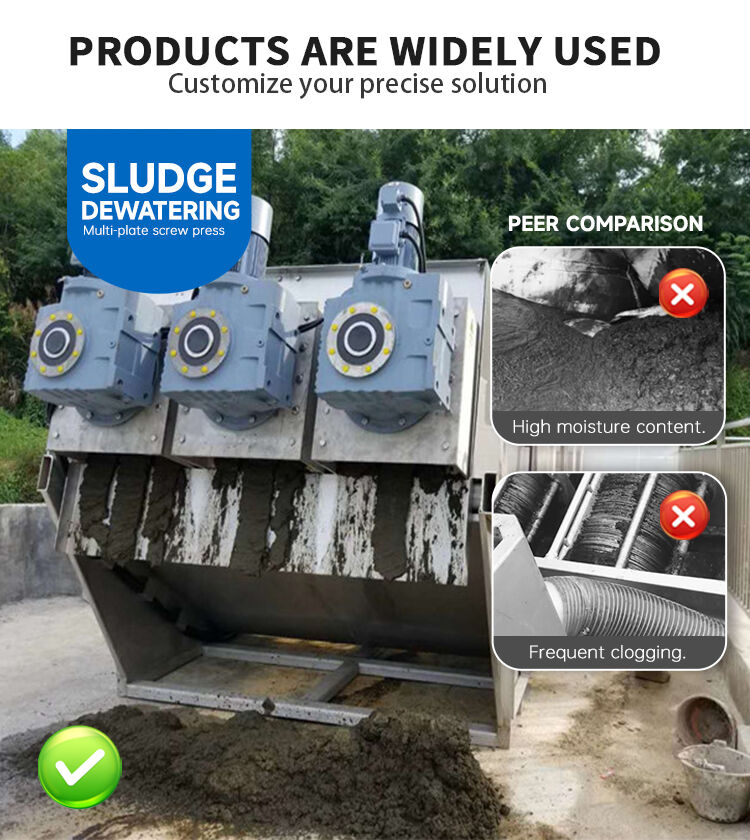

Based on the sludge flow and concentration detected,the automatic dosingsystem adjusts in real-time to

ensure the optimal dosage ratio, resulting in stabledewatering performance and consistently high-quality

sludge cake.

100%o premiumRaw materials

Crafted from stainless steel, it resists corrosion and rust. Fixed and movable rings are stacked alternately,

with a multi-layer screw shaft running through the entire set of rings.

One-touch operationfor full automation.

One-touch start/stop, auto-cleaning,and fault alerts. Syncs with theauto-dosing svstem to adjustchemical

feed based on sludge flowand concentration, ensuring peakefficiency and minimal chemical use.

Core ComponentsPowered by leadingInternational brands

Featuring Siemens, Grundfos,Schneider, ABB, and NORD corecomponents - ensuring 40%lower maintenance

costs withhigh-efficiency operation.

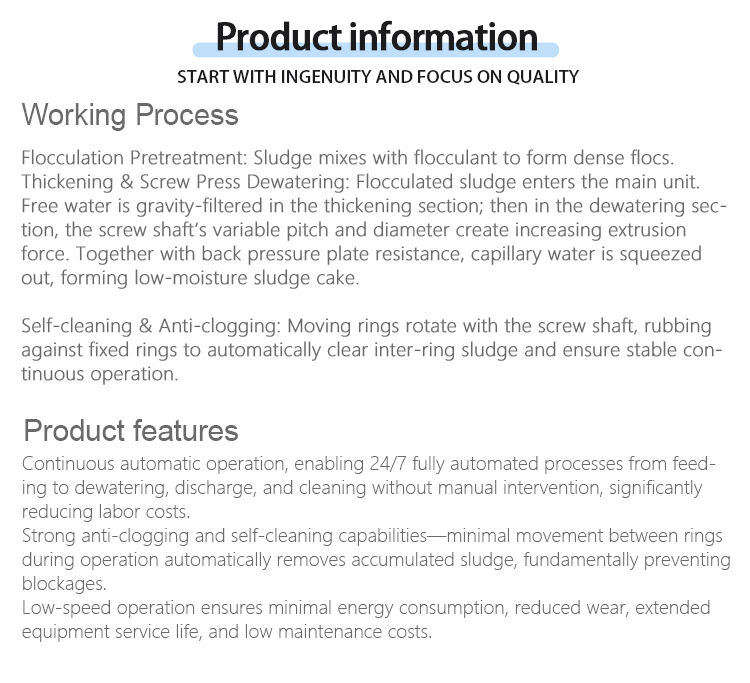

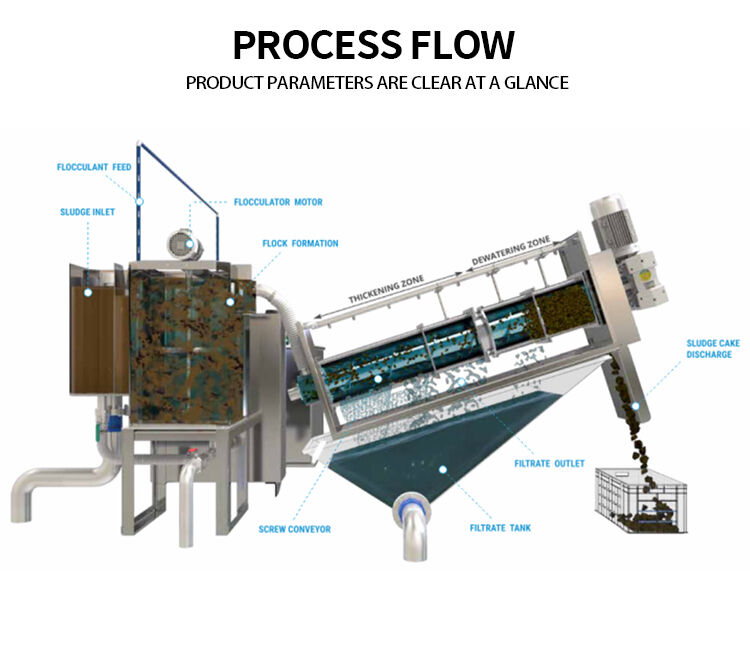

Working Process

Flocculation Pretreatment: Sludge mixes with flocculant to form dense flocs.

Thickening & Screw Press Dewatering: Flocculated sludge enters the main unit.Free water is gravity-filtered in

the thickening section; then in the dewatering sec-tion, the screw shaft's variable pitch and diameter create

increasing extrusionforce. Together with back pressure plate resistance, capillary water is squeezedout, forming

low-moisture sludge cake.

Self-cleaning & Anti-clogging: Moving rings rotate with the screw shaft, rubbingagainst fixed rings to automatically

clear inter-ring sludge and ensure stable con-tinuous operation.

Product features

Continuous automatic operation, enabling 24/7 fully automated processes from feed-ing to dewatering, discharge

and cleaning without manual intervention, significantlyreducing labor costs.Strong anti-clogging and self-cleaning

capabilities-minimal movement between ringsduring operation automatically removes accumulated sludge

fundamentally preventingblockages.

Low-speed operation ensures minimal energy consumption, reduced wear, extendedequipment service life, and

low maintenance costs.

We have more than28 years factory experience in this field and own a professionalservice team and

technical team. Under management system, we control the qualitystrictly from raw material to finished product.

Delivery time

Sample:15 working days after receiving the full payment uniformly;The production lead time is

approximately 30-150 days,depending on customizationrequirements.

Payment methodsT/T, Alibaba Secure Payment, L/C, Western Union, Paypal, Credit Card,etc.

Copyright © Qingdao Yimei Environment Project Co., Ltd. All Rights Reserved Privacy policy